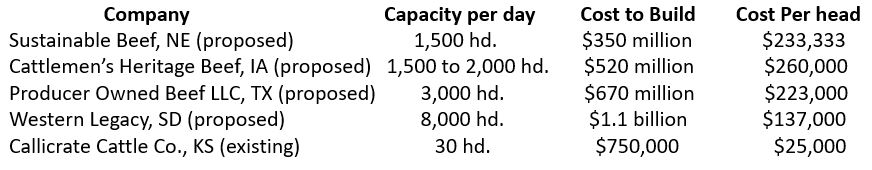

Comparing Local/Regional Meatpacking Infrastructure to Large Centralized Slaughter Plants

Nearly 500 30-head-a-day multi-species slaughter plants, with a combined single shift capacity of 14,000, could be built for the cost of the proposed Sustainable Beef/Walmart plant in North Platte, Nebraska. Additional benefits to the lower cost of this model are:

- Better for animals – The Callicrate plant design locates slaughter facilities where animals are raised, reducing stress and shrink.

- Better for workers: Skilled, well compensated butchers, are more efficient, processing more animals per worker per day, while working at a safe pace in the simple and low cost plant design.

- Better for the environment – More responsible resource management: 30 to 50 gallons of water per animal processed, compared to over 700 gallons for the big plants. Slaughter waste is an asset, not a liability. It is composted onsite into valuable fertilizer. Reducing food miles – fewer and larger slaughter plants has meant animals now travel much further to slaughter.

- Better food safety and quality: Beef carcasses are properly aged, producing a safer, more consistent, higher quality product.

- Better for small business – Small community butcher shops process carcasses into final retail and wholesale cuts, eliminating “The Box.”

- Better for Producers: Selling more direct, bypassing the meatpacker/retail/foodservice cartel, provides more income for producers. Producers selling direct can earn nearly 80% of the consumer beef dollar, compared to 37% selling to big meatpackers.

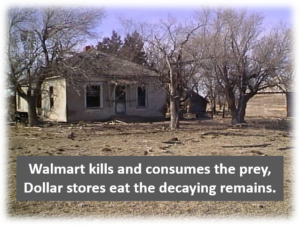

- Better for communities: The Callicrate decentralized model is simple, affordable and regenerative. It conserves and better manages resources, while retaining far more of the wealth created through agriculture in rural communities instead of distant financial centers.

Why build more packing plants designed around the extractive industrial model?

Local/regional supply chains provide healthier, more sustainable food options, feeding producers, workers, and communities instead of corporations. Well designed local/regional food systems are less vulnerable to disruption, providing the critical food security lost from decades of food system concentration and hyper-globalization.

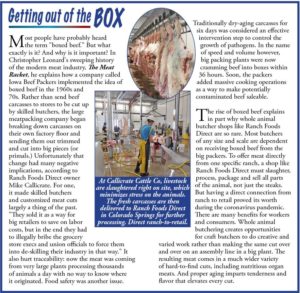

What does a better meat industry look like?

Design by Teegan Callicrate, Callicrate Manufacturing, St. Francis, Kansas

Skilled butchers processing carcasses means better jobs, affordable prices, and safer, higher quality food for communities, both rural and urban.

Connecting the Community at the Source of Their Food

Producers, makers, and consumers gather around good food from the community and region.

Related:

Meatpacking infrastructure of the future

Industrial Agriculture and Urban Sprawl – A model of growth that’s made to fail.

Packer Concentration in the Beef Industry, By Kathleen S. Kelley

How “The Box” captured the meat industry

Story of the Steer – Big meatpackers and retailers trade lower efficiency for higher profits

Congrats – I came to St Francis to learn how you were doing it with cattle to bring back to pork producers starting to do the same.

20 yrs later no pork plant, more consolidation, thousands of loss producers but you are thriving. Sinatra ‘You Did It Your Way’. Impressive.

Wish I was able to see your companies operation.

From Johnny Weaver:

I hear a lot of times, almost like a broken record, cattle people giving an objection to fixing a broken market with … THAT WON’T SUPPLY THE COUNTRY.

Serious question for any cattle operation, when did a angel descend down from heaven and tell you, it’s YOUR responsibility to feed the WHOLE COUNTRY??

Do you want to take Shrimpers job?

How about pig farmers job?

Chicken farmers?

Lamb and Goat ranchers job?

Ranch raised catfish?

I mean that is what the Industrialized Beef Industry has for a goal … is that Your goal too?

Their goal is all about VOLUME and $$$$$

Here’s last weeks over 80% Choice Negotiated sales for steers:

1225# @ $1.46=$1788.50

1625# @ $1.40=$2275.00

Avg 1496 # @$1.43=$2139.28

[Big-box retail value is nearly $5,000 per head]

The difference between the 1225# steers and 1625# steers was $486.50

More for the VOLUME FEEDER.

You know what TRICKLED down to those calves you produced? THAT $1.43 😂😂😂

To be profitable and stay in business you as cow/calf operators need a PROFIT for what you produce and you shouldn’t have to jump through hoops to get it, they sure as hell don’t.

Mike, do you process (USDA) for small producers? We are having a heck of a time getting appointments in a reasonable amount of time.

Hi Ron, About half our slaughter and processing business is for other producers. Unfortunately, we are fully scheduled with our current customers livestock considering our current availability of workers. We need more skilled butchers asap.