The May 13th article, Soaring Earnings of Chipotle’s 2 Bosses Raise Investor Unease, inspired the following story of my experience with Chipotle:

Years ago, when I first saw the Chipotle big burrito, “Food with integrity” bill board, I thought what a great marketing campaign. But was it true?

I was part of an effort at Colorado College to replace Sodexo with Bon Appetit. Sara, a young student activist was leading the charge. We were successful. Bon Appetite is now one of Ranch Foods Directs best customers. Colorado College students are now eating well. Sara went to work for Chipotle upon graduating. She arranged a meeting for me to talk about working with Chipotle in the local area. June 2010 was our first delivery to the Colorado Springs Chipotles. I was very enthusiastic about the possibilities, especially the possibility of a national chain food company developing logistics that allowed the use of local food – acting in a way that builds communities instead of extracting from them. It hadn’t been done before.

Things couldn’t have gone better. The quality and consistency was great, customers were loving it. Pricing worked. Head purchasing agent, Doug George, was happy with our facilities, our product and my humane, no performance enhancing drugs and overall methods of production. My protocol of production affidavit and other agreements were on file with the company. A $185,000 slicing machine was put to work at Ranch Foods.

I stopped by the Chipotle headquarters in Denver sometime following our start of doing business. After a successful meeting with Doug George and Sara, Sara informed me confidentially that she would be leaving Chipotle. I asked why? She simply responded, “Tyson chicken?”

Chipotle produced the video, “Back to the Start”. It’s the story of hog farmer, Russ Kremer. Like myself, Russ left the university in the middle 1970’s with a model of industrial factory farming in his head. He realized later his training in animal science was a long way from animal husbandry. I promoted the film and it’s message in speeches and presentations. I was worried about the “Tyson chicken”, but thought the company was headed in the right direction. I believed a new day was possible for family farmers and ranchers to access the marketplace at a fair price and in a big way. Shareholders appeared to support sourcing good healthy food from family farmers.

We had been asking Chipotle staff to visit our cattle operation in St. Francis, KS since we started doing business. Finally in August 2012, three Chipotle representatives came to visit the cattle operation. We had a full day planned beginning in St. Francis, ending the day at the processing plant in Colorado Springs. They toured the plant the following morning.

I had an ugly feeling that something was up after I met Joel Martin, one of the three Chipotle representatives and former Meyer Natural Angus (operates under the Cargill umbrella) employee. Joel pretty well knew the business, but was describing a protocol different than the one agreed upon with Chipotle.

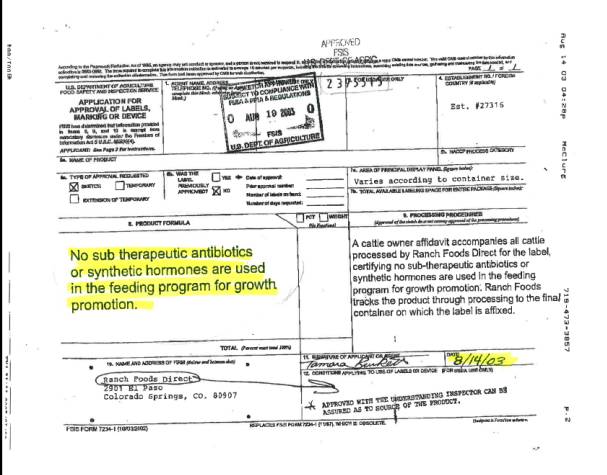

I have argued for years that the “never-ever” antibiotic and hormone protocol was a fraud. In the best of management and production programs an animal will still get sick and deserves good animal health treatment with all the withdrawals adhered to. I’ve watched the Coleman “never-ever” beef program for the last thirty years and knew how false affidavits were being used to qualify cattle for the premium prices. Starving ranchers and feeders were being asked to do the impossible, so they were cheating – and still are.

The protocol I registered with USDA accounted for the misuse of antibiotics while still leaving the possibility of responsible antibiotic use for treatment when needed. Chipotle had agreed it made sense.

By the end of the day of August 5, 2012, I was done selling to Chipotle. No mention of my investment in equipment and inventories of meat. Simply, “You don’t meet our protocol. We have to move on.”, click. Joel Martin didn’t like that we branded our cattle, he didn’t like our method of horn removal (a rare occurrence with Angus cattle), our method of castration (I invented the humane, bloodless and drug free method) or that we fed milk replacer to calves that lost their mothers, he didn’t like our USDA inspected mobile slaughter unit, and he didn’t like that Ranch Foods Direct was buying beef in addition to my Callicrate Beef, from other producers operating under the same RFD protocol (building a new local/regional food system). But he did suggest that Chipotle could continue buying From Ranch Foods Direct if we would take a lower price.

I learned that Chipotle was being sued by their shareholders for poor financial performance (not anticipating the increase in food prices after the 2008 run-up). Perhaps a motivation to reduce food costs?

Joel Martin was demanding a protocol of production that he knew was impossible to produce – a protocol not-to-buy. Chipotle could say they were doing the best they could, but were forced to buy in the commodity market. Of course plans for aggressive expansion continued, despite the fact that they had not met the “food with Integrity” promise on their existing stores.

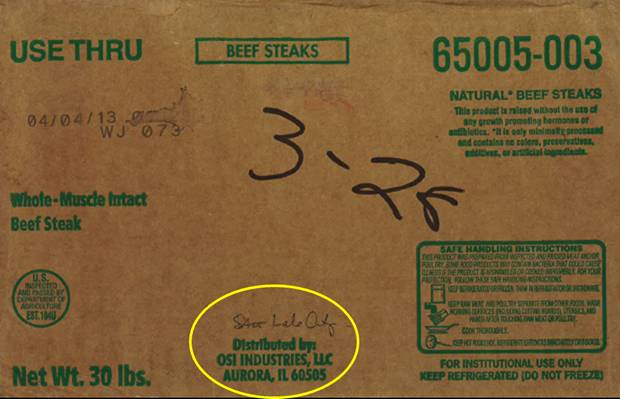

The Colorado Springs Chipotle’s replaced the good beef from Ranch Foods Direct with meat from OSI Industries:

OSI is a very large multinational corporation operating out of 50 locations in seventeen countries. OSI has a strategic partnership with Marfrig, the second largest meat packer in South America. Some of the cheapest beef in the world comes from South America, which is suffering ongoing problems with Hoof and Mouth disease (HMD) and recently reported a second case of Mad Cow Disease (BSE).

OSI push into poultry production in China: ‘It’s a different model’

By Rita Jane Gabbett on 3/19/2014

CHICAGO — Four years ago Aurora, Ill. based OSI Group decided to start growing and processing its own chicken in China to better serve its large food service customers like McDonald’s and Yum! Brands. From a new operation set to start production this year, OSI will grow and process 120 million chickens per year.OSI Group Chief Financial Officer Bill Weimer told participants at The State of Food and Agribusiness conference here that the chicken business in China is a different model and the company is still honing its business model there.

OSI entered the Chinese market to better control the food safety aspect of the chicken it provided its customers. Unlike the U.S. poultry industry model, this meant investing millions of dollars per grower operation. In addition, grain is produced on such a smaller scale and in such a more fragmented way that feed costs are nearly double those in the United States.

Perhaps the biggest challenge, however, has been finding a market for the breast meat OSI produces in China. The company sells mostly dark meat and wings to McDonald’s and Yum! Brands in that market.

So far, Weimer said, most Chinese consumers have not valued the higher cost of production implicit in OSI’s state-of-the-art production and food safety practices. He said the company must seek out affluent Chinese customers in urban centers such as Shanghai, as well as find export markets for these chicken parts not needed by its key food service customers.

The law firm Mayer Brown hosted the conference.

OSI is one of three large companies in the country with the capacity to cook pathogen contaminated meat (there’s a lot of it these days) for sale as pre-cooked, value-added items and meals.

Instead of the promises of the marketing department aligning with operations, it appears that they continue to further diverge.

It is important to note that the combined annual CEO salary is 2,800 times more than that of the starting “Crew Member’s” annual income (based on the $8-$9 hourly wage and a 40 hour work week). The co-CEOs make in 45 minutes what their beginning workers make in a year.

Family farmers and ranchers are still waiting for the opportunity to sell into a fair marketplace.

Mike Callicrate

Ranch Foods Direct